Explosion-proof sewer inspection technology from IBAK

Explosion protection, as a subarea of safety engineering, is standardised worldwide. The concepts and measures are subdivided by methodology and serve to prevent explosions and thus to provide precautionary protection for persons and objects in potentially explosive atmospheres.

Explosion hazards in sewer systems

Explosion hazards in sewer systems can be caused by the following events:

- Intrusion or discharge of gases, vapours or flammable liquids

- Sewer gas emissions from wastewater and sewage sludge over long transport distances or long storage periods

- Leakage of sewer gas from pipes carrying sewer gas

Applications of sewer pipe and manhole inspection systems

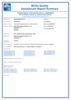

Only explosion-protected equipment with a reliable type of explosion protection may be used in hazardous areas. The Ex areas are internationally based on the 3-zone classification (according to IEC, NEC 505 and CENELEC):

- Zone 0: explosive atmosphere is present continuously, for long periods or frequently

- Zone 1: explosive atmosphere is present occasionally

- Zone 2: explosive atmosphere is present infrequently and for short periods of time

The European Directive 2014/34/EU is based on the same classification in terms of content and, with the ATEX zoning (AtmosphèresExplosibles), only distinguishes between atmospheres with gases and vapours (ATEX zones 0, 1 and 2) and areas with dusts (ATEX zones 20, 21 and 22).

IBAK offers certified explosion-proof inspection systems for all environments in which an explosive atmosphere may occur occasionally (zone 1) or briefly (zone 2).

Tested and certified quality in explosion protection

The devices and components used must be able to be deployed safely and function reliably in the event of potential hazards and under the toughest operating conditions. This places high demands on product quality and requires corresponding expertise in the design, manufacturing and testing process.

IBAK equipment and protective systems are regularly certified for their intended use in potentially explosive atmospheres on the basis of test regulations which are recognised in many countries around the world (IECEx).

Our customers benefit from decades of experience and current knowledge in these safety-relevant areas and can rely on certified quality and safe use.