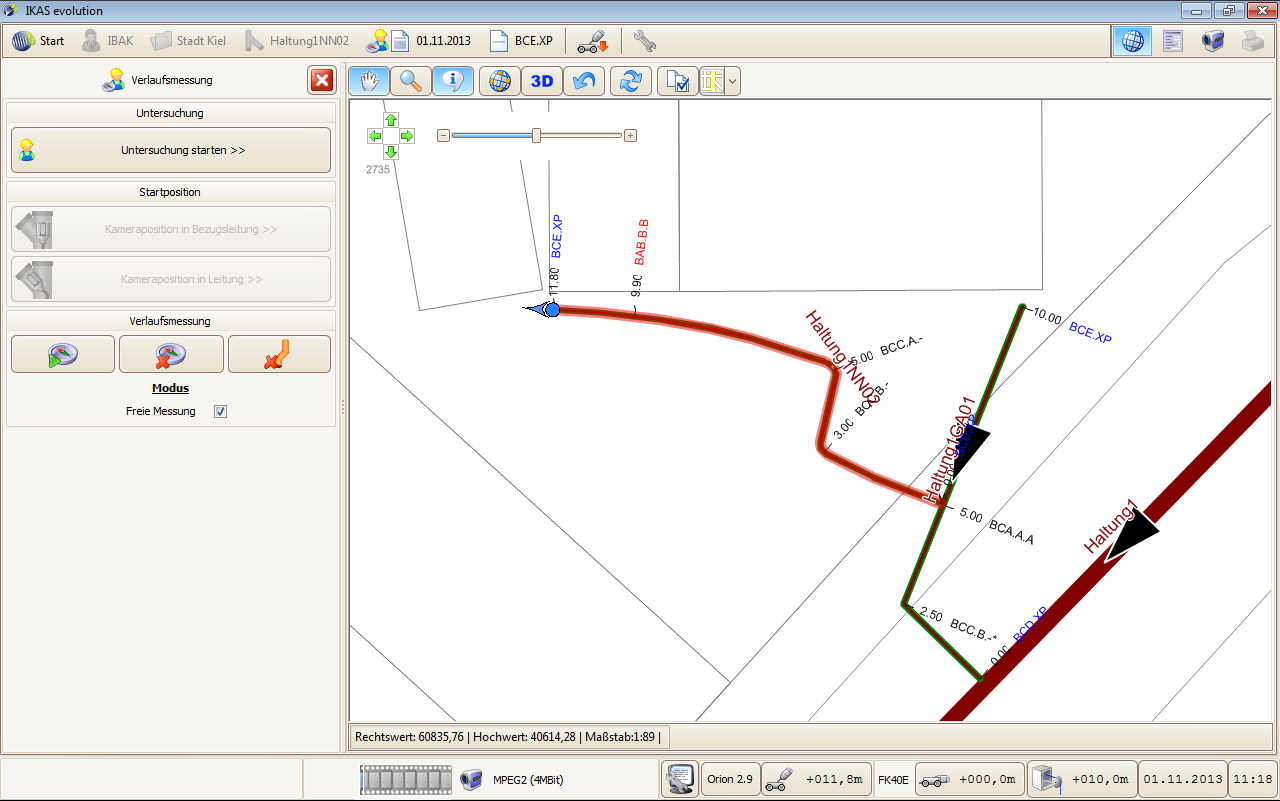

Pipe route measurement in main sewers and ramified pipe systems

In the case of complex and ramified pipe systems, precise knowledge of the actual pipe route and position is an important prerequisite for maintenance and exact damage localisation.

The pipe route measurement is automatically recorded and the xyz coordinates determined in the same work step as the inspection via a 3D sensor integrated in the camera.

With an additional hydrostatic height measuring system, the height can be determined with centimetre accuracy and the z-axis data verified.

Precise measurement of height differences

Hydrostatic height measurement is a system developed by IBAK and proven in practice to determine elevation points for the verification of pipeline routes.

It is an ideal supplement for the holistic detection and measurement of pipes in pipe networks in addition to 3D GeoSense pipe route measurement.

Decisive advantages of pipe route measurement

- Precision: Geodetic recording of position as a basis for all value-preserving services related to maintenance

- Efficiency: Inspection and measurement in a single operation saves time and costs

- Flexibility: The measuring system provides realistic results in both push and cleaning mode

- Quick responsiveness: Sensor data is visualized in real time and dynamically transferred directly to the network graphics

- Simplicity: Operation, data processing and transfer are process-safe and interface-compliant