More than a glimpse into the future at RO-KA-TECH 2023

Forward-looking inspection

Optimised handling and high resolution were features of the highlights in the field of sewer inspection. The lateral inspection system LISY which can be quickly adapted to changes of diameter by means of lateral guides and remote-controlled height adjustment attracted particular attention. The system can be introduced into sewers through a manhole when fully assembled, even in the setup for pipe dimensions of DN 2000. The process of turning off into laterals from main sewers can be monitored in full HD.

The AutoPush system with which the push rod can be automatically driven forward into the pipe was demonstrated on the mobile push rod camera system MiniLite. In combination with the aiControl operating concept which is based on methods of artificial intelligence (AI), the ORION L camera was guided by autopilot through the freely configurable pipe course. With the assistant system, the camera turned off fully automatically into laterals, detected joints and panned automatically around them.

Comprehensive rehabilitation options

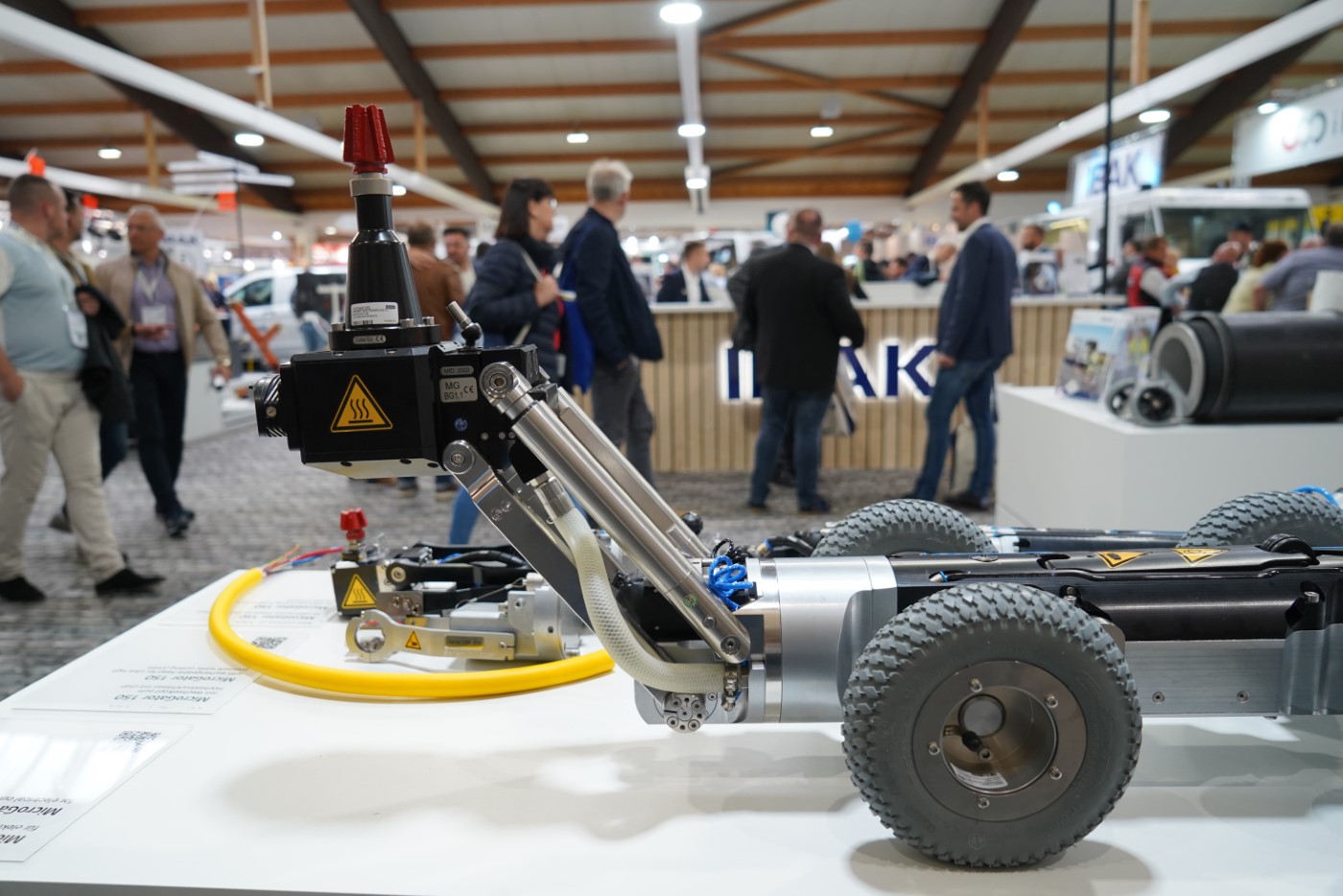

The focus was on flexibility and versatile operation with regard to sewer rehabilitation. On show was the wide spectrum of rehabilitation techniques that can be performed with the electric cutting robot MicroGator. Also exhibited was the electric MicroGator 150 that can be operated in main sewers of relined DN150 upwards and that is equipped with a system of exchangeable heads for versatile tasks. With the pneumatic cutting robot MicroGator Air, the emphasis was on its compatibility with the MainLite system: the multifunctional solution permits high-performance cutting and inspection to be carried out in main sewers.

Intelligent software solutions

Last but not least, the software range attracted a great deal of attention – in particular ArtIST, the cloud-based extension to the IBAK sewer analysis software IKAS evolution. The tool on the basis of methods of artificial intelligence automates condition data capture. During our discussions in Kassel, it was made quite clear that the established market structure with contractors and customers of inspection services is retained with IBAK ArtIST.

Kassel is followed by workshops

“With everything we do, we take care to ensure compatibility and modularity so that the investments of our customers are sustainable and safe. Even if some of the things we have shown here in Kassel are dreams of the future, the reliable working bases of our users have already been prepared today for the new possibilities of tomorrow. We are moving forwards together step by step, and this has proved its worth for decades,” emphasises Dorian Hunger, a member of the IBAK management.

“Impressed by the great number of visitors and the positive feedback, we are now looking forward to our workshop series in Germany and Austria. The subject matter 'Sucess factor workflow – with efficient processes to increased productivity' is a direct follow-up to Kassel. It is worthwhile visiting our website, not only to register for the workshop but also because we have completely redesigned the site. It went live directly for the Ro-Ka-Tech,” says IBAK senior executive Janina Galinski in conclusion.