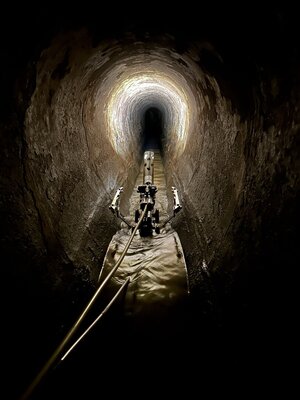

LISY inspects from the main sewer

Systems and technologies involved

- Satellite system LISY with LIFT, LateralGuides and egg-profile carriage

Job

Schweinfurt is an urban municipality in the administrative district of Lower Franconia in Bavaria and has a population of more than 54,000. In Schweinfurt, some 20,000 m³ of sewage is produced per day. The Schweinfurt Sewage Department has been a municipal enterprise of the City of Schweinfurt since 1996. They commissioned Schnurrer Kanaltechnik GmbH (Schnurrer) from Weiden with the inspection of a total of 27 km of main sewers with diameters of DN 150 to DN 2800. The irregular sizes and large-diameter pipes (with ovoid cross-sections of 700/1050 to 1500/2250 and irregular profiles of 500/962 to 1029/1800) extend for a distance of four kilometres.

The Rückertstrasse in the historic city centre needs a new surface in the middle as there is a heavy strain on this area: some 145 buses drive over the road surface each day. Rehabilitation measures may also be necessary in the pedestrian zone. Because of this, Schweinfurt Sewage Department required the results of the TV inspection quickly for further planning and accordingly prioritised the main sewer underneath it with a length of 325 metres. So Schnurrer started the sewer inspection with the seven reaches of brick-built sewers with an ovoid cross-section of DN 800/1200.

Challenge

"The reaches are located directly by a pump station that switches on roughly every 10 minutes. This means that we are continuously confronted with sewage flowing at a high speed during operation," inspector Rudolf Ambrosch explains. "If we had shut off the sewer, we would only have been able to work for an hour at the most, then we would have had to wait half an hour. That wouldn’t be efficient," the Schnurrer employee continues. In any case, fast work was required, so as not to hamper the bus and other road traffic and to provide the inspection data promptly as a basis for planning. "Along the way, there are lots of difficult 90-degree bends in the laterals, because the public sewer was reinstalled at a lower level years ago. Some of the bends go upwards by an angle of even more that 90 degrees, run on that level for roughly 3 metres and then return to the horizontal so that they come back to the old sewer," Peter Kreinhöfner, the responsible Schnurrer engineer explains. In view of this background, bend-negotiating capability is an essential requirement on the equipment used.

Solution

IBAK implemented the deployment range of up to DN 2000 among other things with a new funnel concept, the LateralGuides, the LIFT and an elegant insertion curve that optimally guides the push rod. This was used extensively in Schweinfurt in challenging conditions. Over the distance of the 325 metres, 54 laterals with diameters of DN 150 to DN 200 were inspected from the main sewer with the ORION. The laterals were mainly in the 10 o‘clock and 2 o’clock position. "Part of the inspection was performed with our LISY in flushing mode; we inspected the greater part with the LISY 4 in push rod operation," Ambrosch reports.

Result

The LISY 4 could be lowered into the sewer fully mounted with the LIFT, the funnel and the ovoid profile carriage. The exact position of the ORION 3 HD could be seen via the control camera, and this helped Ambrosch to insert and advance the inspection camera. "We were able to ascertain a definite difference to our existing system: with the LISY 4, the funnel remains stable in the pipe even in difficult conditions." The push rod could be guided into the lateral in a more controlled manner. This is achieved by a harmonious overall curve from the invert into the lateral. Thanks to this harmonious curve, the push rod is optimally guided, so that the propulsion power is almost entirely available for propulsion into laterals. This is clearly shown by this practical operation: "It really went fantastically well. I was very surprised how far we got into the laterals. We got in further than with our LISY in flushing mode. In some cases, we got up to 20 metres into the laterals in spite of the 90-degree bends. Without flushing, I would never ever have managed that in these operating conditions with the old system," the experienced inspector affirms.

That the rotary drive with which the funnel is swivelled to the entrance of the lateral keeps the funnel actively in position was particularly convincing. Inspection lengths of up to 22 metres could be achieved without flushing with the LISY 4, whereby 90-degree bends had to be negotiated. In spite of difficult operating conditions – such as water flowing a high speed – there was never any danger of tipping. In direct comparison, Schnurrer ascertained it was possible to work faster with the LISY 4.

Company introduction

Seit 2010 ist Schnurrer Kanaltechnik als eigenständige Firma aus der Josef Schnurrer GmbH & Co. KG, einem Produzenten von Betonrohren, Beton- und Stahlbetonfertigteilen, ausgegliedert. Mit 15 Mitarbeitern auf der Baustelle deckt das Unternehmen in etwa gleichverteilt die beiden Bereiche Kanalinspektion und Kanalsanierung ab. Im Büro sind weitere fünf Mitarbeiterinnen und Mitarbeiter beschäftigt. Rudolf Ambrosch ist seit über 10 Jahren bei Schnurrer als Inspekteur tätig.

Der gelernte Beton- und Stahlbetonbauer bereut nicht, in die Kanalinspektionsbranche gewechselt zu haben: "Nur im Büro sitzen, wäre nicht meins gewesen. Als Inspekteur ist es abwechslungsreich: man ist mal drinnen und mal draußen". Der 63-jährige macht sich Gedanken über den Nachwuchs für diesen Beruf: "Die Aufgabe wird komplexer, man darf keine Scheu vor dem Umgang mit Software haben, und trotz allem was es Neues gibt, braucht man ein Auge für Proportionen und die Bereitschaft, sich auch mal schmutzig zu machen. Die Arbeit hat sich gewandelt, man steigt heute längst nicht mehr so oft in den Schacht ein, wie früher. Es gibt aber nach wie vor Situationen, in denen dies nötig ist." Schnurrer bildet zur Fachkraft für Rohr-, Kanal- und Industrieservice aus und ist zudem auf der Suche nach Teamverstärkung; auch Quereinsteiger sind willkommen. Das neue Teammitglied kann dann den weiteren Verlauf des interessanten Projekts in Schweinfurt aktiv begleiten. Sicher ist bereits, dass die neuste Generation der LISY dabei sein wird: Nach diesem erfolgreichen Probeeinsatz entschied sich Schnurrer die LISY 4 anzuschaffen und diesen sowie viele weitere Aufträge damit optimal abzuwickeln.