Continuous measurement of pipes with ovoid cross-sections

Job

The municipal sewage department of the city of Dortmund with nearly 600,000 inhabitants operates a 1,996 km long, widely ramified sewer system. The municipal enterprise has commissioned VOGEL Ingenieure GmbH to plan the renovation of combined sewers in need of rehabilitation. The declared aim of the project is to preserve and modernize the sewers, which were built between 1882 and 1920. The municipal sewage department the city of Dortmund attaches great importance to experienced and comprehensive planning, since this contributes considerably to the results of a rehabilitation measure. VOGEL Ingenieure GmbH recommended that the real profile dimensions should be determined in the course of the optical inspection, which is required anyway.

Challenge

The construction method used at the time was hydraulically favourable with partly curved pipe routes. Some of the lateral inflow pipes of even the major collectors are connected to the main collector without direct accessibility, e.g. in the form of an inspection chamber. The wastewater facilities concerned are mainly located in heavily frequented traffic areas, in the pedestrian zone and main shopping streets, and this places higher demands on the organization of the construction site. For road safety, permits required under road traffic legislation were obtained in coordination with the highway authority. In order to obtain information of a sufficiently good quality, the sewers to be inspected were taken out of service and the outflows diverted. The reaches were cleaned in advance by high-pressure jetting. Isolated results of TV inspections from the years 2006 to 2014, digital site plans and the data of manhole inspections were available as initial data. Several accompanying services that were required in order to carry out the optical inspection of sewer reaches and manholes and profile dimensioning were performed by various service contractors. VOGEL Ingenieure GmbH took over the complex overall coordination in order to ensure smooth handling of data acquisition and correlated timing of all work steps.

In addition to the existing data, local measurement of manholes has become established as a standard. In walkable sewers, additional point measurements of the diameter have been carried out up to now. However, the circumference of brick-built sewers can change within a few cm. With point measurement at the pipe ends, varying inside diameters over the run of the reach are not detected and thus not considered during the further procedure. At best, erratic changes in the nominal diameter over the run of the reach are taken into account for pipe liner design.

Solution

These changes of diameter can usually be detected during optical inspections. However, changes of diameter can also be gradual, so that they are not visible to the naked eye. But the most accurate as possible knowledge of the actual profile is relevant for the fabrication of the pipe liners with the aim of achieving a technical service life of at least 50 years.

The optical inspection was carried out with the IBAK ORPHEUS 2, which enables the profile dimensions to be determined over the entire length of sewer reaches with ovoid cross-sections thanks to the lasers integrated on the fully rotatable camera head. The laser scan was performed immediately after the optical inspection while the camera was on its way back from the target manhole to the start manhole. The inspector started the scan for the continuous profile analysis using the IKAS evolution software. Since the lasers are integrated into the inspection camera, the laser measurement system did not have to be mounted in front of the camera with a bracket. This eliminates additional mounting work for the inspector and the recording process for profile analysis fits perfectly into the TV inspection workflows.

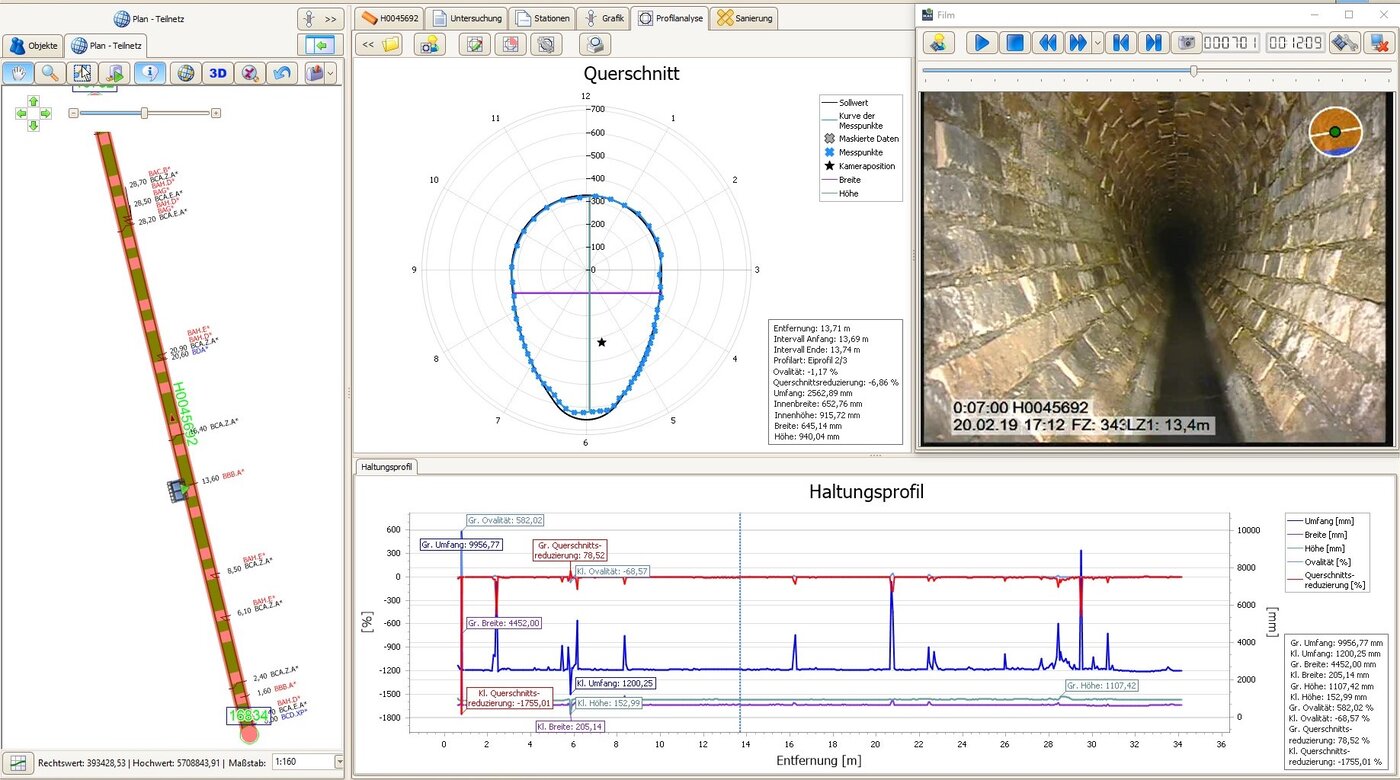

When the operating mode is switched from inspection mode to laser scan mode, the lighting is automatically switched off, the laser measurement system is automatically switched on, and the camera is automatically aimed at the pipe wall. On the basis of the two laser points, the system determines the distance of the camera to the pipe wall. Finally, when the system moves back out of the sewer while the camera is rotating, the entire profile of the reach is captured. A spiral of laser measurement points is created. If the camera is retracted faster, larger, elongated spirals are generated as fewer laser measurement points are captured. The slower the camera is retracted, the narrower are the spirals that are formed, as the laser point measurements are captured at closer intervals. Since the centre of the pipe is calculated from the captured values, the middle axis of the camera head does not necessarily have to lie in the middle axis of the pipe.

The laser points acquired in this way were analyzed with the IKAS evolution software and evaluated by the planners at VOGEL Ingenieure GmbH. Users can choose whether to perform the analysis at the workstation in the TV van or at the PC in the office. The choice of the appropriate procedure depends decisively on the application. Since the intended use of the measurement data ranges from construction or warranty acceptance tests through to the selection and dimensioning of pipe liners, there are different requirements for proper post-processing of the measurement results. In the context of the inspection described here, data processing was carried out by the experts of VOGEL Ingenieure GmbH using the Profile Analysis Office version.

Result

As part of the preparations for a continuous measurement by laser of sewers with egg-shaped cross section, deposits were to be removed by cleaning measures and loose deposits were to be reduced to a minimum during the laser scans. With the IBAK ORPHEUS 2 pan and rotate camera, it was possible to carry out a continuous, laser-based profile measurement of the sewers with egg-shaped cross-section in Dortmund. This could be done without additional time for laser mounting. The evaluations carried out on the basis of the measured data could be clearly displayed and comprehensively analyzed by means of the IKAS evolution software. The water that was standing in parts of the sewer could be eliminated from the measured values for calculation of the inner circumference dimensions. Laser scanning of the sewer reaches provided data and thus information that went far beyond that of a purely optical inspection. This applies in particular to the determination of the actual profile dimensions.

Since the planning of Dortmund's sewage department envisages the rehabilitation of the sewer pipes with egg-shaped cross-section by means of the liner method, the data from the laser profile dimension measurement is decisive for the selection and dimensioning of the pipe liners. After measurement of the maximum and minimum circumference over the entire length of each sewer reach, pipe liners whose stretching capability optimally matches the actual profile dimensions can be selected in the further course of the project. This prevents the pipe liner from not fully adhering to the pipe wall due to insufficient stretching capacity or from being damaged during installation.

In addition, further preliminary investigations such as soil examinations and static calculations were carried out for the pipe liner systems. All the information obtained will be combined into a holistic rehabilitation concept and the implementation will be put out to tender.

Company introduction

Das Ingenieurbüro VOGEL Ingenieure GmbH besteht seit 1999 und ist an den Standorten in Kappelrodeck, Bad Krozingen und Ditzingen vertreten.

Das Büro zeichnet sich durch seine hohe Fachkompetenz in der Sanierungsplanung aus. Damit zusammenhängende Leistungen wie die Bestandsdokumentation, Bedarfsanalyse und Zustandsbeurteilung gehören ebenfalls zum Portfolio.