MicroGator equipment carrier controls ultra-high pressure water jet

Jobs

Steinharte Versinterung

Kleinbottwar is a district in Steinheim an der Murr in Baden-Württemberg. The Wehrbachsee lake and dam located there were the site of operation for A&T Rohrreinigungs-GmbH. It received an order from the responsible municipal sewage department to clean and inspect the drainage pipes under the area in agricultural use.

Challenges

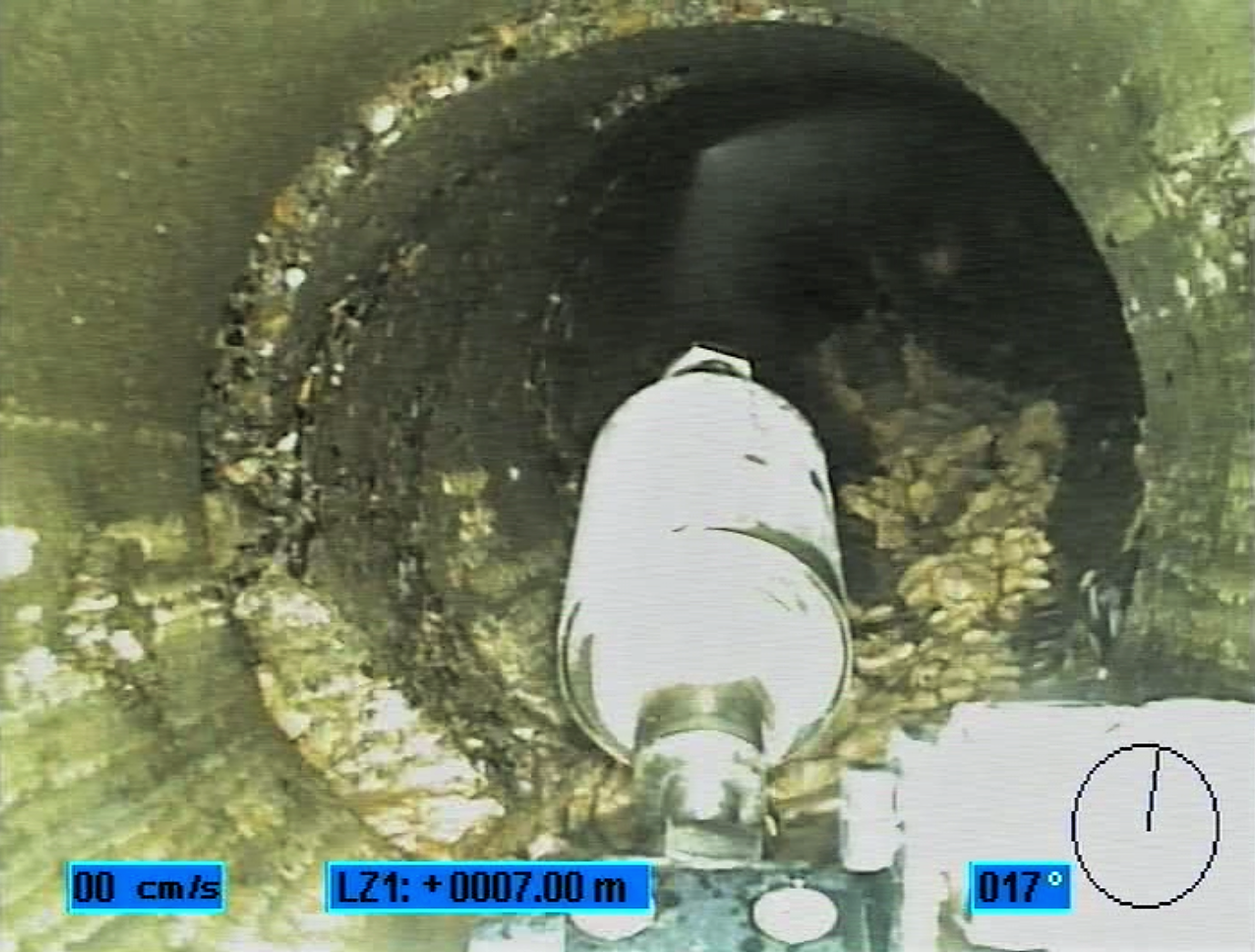

The pipeline in Kleinbottwar was a concrete pipe in circular profile DN 250, which was sintered with lime deposits over a wide section up to almost two thirds of the height, whereby these showed an extreme hardness. As a result, the flow was severely restricted. With the aim of preventing further growth of the sintering and thus a complete closure of the concrete pipeline and, moreover, to make the pipeline fully functional again, IBAK Robotics and falch were given the opportunity to demonstrate the robot-guided ultrahigh-pressure water jetting technology in a trial application.

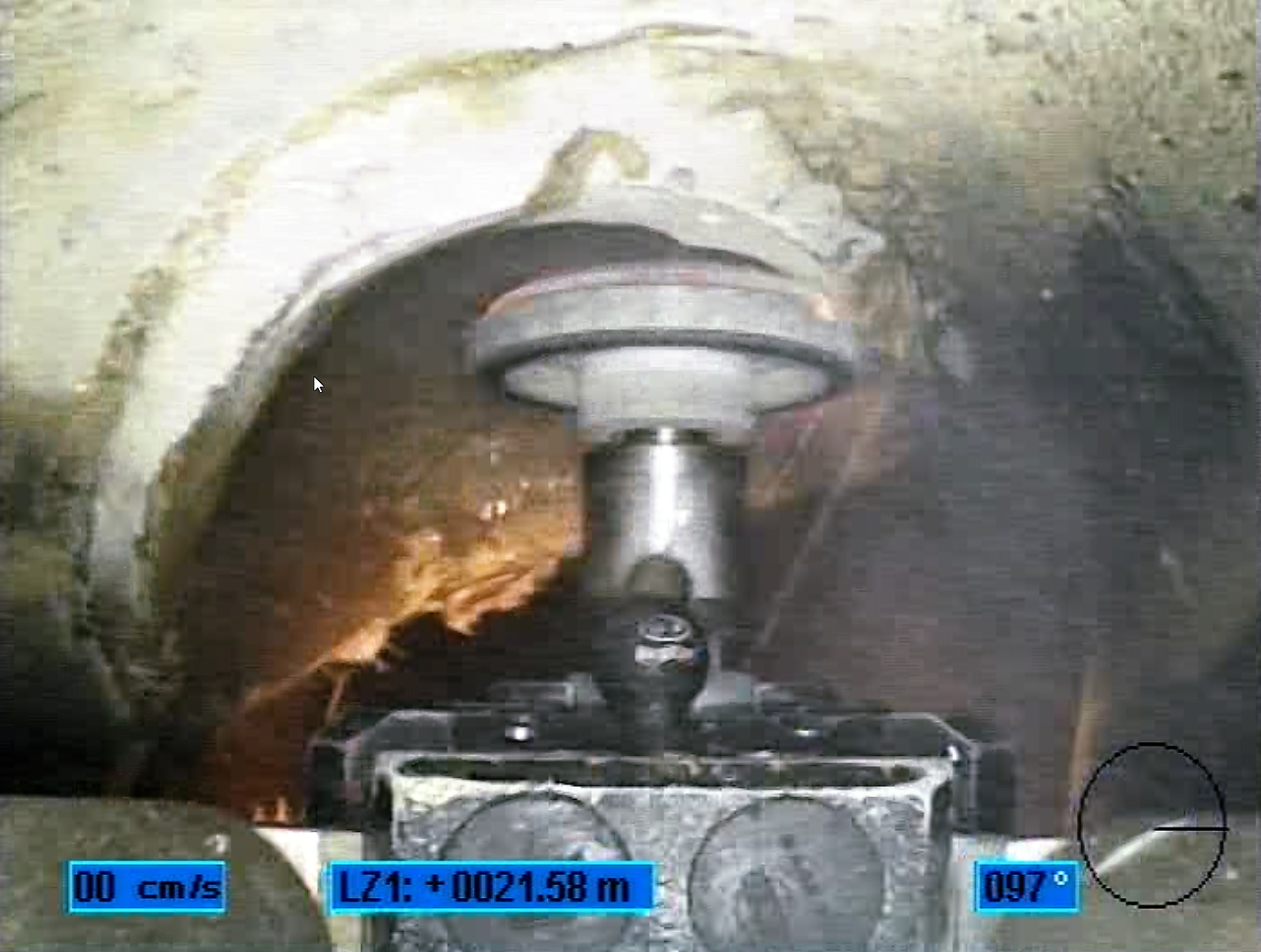

In Sillenbruch, the extensive root rot had to be removed quickly and completely from the DN 300 PVC pipe. In addition, an approximately 10% protruding spigot represented a drainage obstacle in this PVC pipe. Electric milling with cutter heads is still appropriate for precise, point-by-point processing of pipes.

Solutions

The MicroGator equipment carrier, to which the magnetically braked falch ultrahigh-pressure waterjet nozzle Drainspeed 30 was adapted, was driven against the direction of flow at continuous speed. It was operated at 2500 bar and 24 l/min. The rotation with the falch X-Jet cross jet head achieved a very good shearing effect without damaging the pipe wall. The solidified massive deposits were crushed piece by piece under camera observation and then flushed out of the drainage pipe.

In order to subject only the foreign body to be removed and not the pipe itself to high stresses, a somewhat flatter angle of attack of the 4-jet falch Pointspeed 30 4/2 rotary nozzle with constant speed was selected under camera observation. The tightly interwoven solid root strands could be removed flush with the pipe wall at 600 bar and 24 l/min and at continuous speed of the MicroGator equipment carrier and quickly crushed. For precise, point-by-point processing of pipes, electric milling with milling heads is still appropriate. Here, the MicroGator was used, which can be operated on the same system as the equipment carrier for the waterjet ultrahigh-pressure technology. Using the mushroom head attachment with diamond coating, the protruding spigot was milled flush with the inner wall of the pipe.

Result

The positive results of the trial operations by IBAK Robotics and falch have shown that robot-guided ultra-high-pressure water jetting technology can be used to remove extensive deposits in a way that is fast, economical and gentle on the pipe substance. Controlled water jetting technology is a practical supplement to electric cutting in the case of metre-long blockages in pipes. Where there are extensive deposits of a solid character over a large area, water jet technology is the more economical option. The electric cutting robot, on the other hand, is predestined for precise work such as smoothing protruding pipe connections and misplaced joints and opening laterals after the installation of pipe liners. The fact that both processes can be operated on the same system and that it is therefore possible to switch flexibly between the methods within a single job was particularly convincing.

Company introductions

The medium-sized company A&T Rohrreinigungs-GmbH from Stuttgart-Zuffenhausen has been active in the field of pipe and sewer cleaning since 1986 and offers its services for both the private and commercial sector in the region as well as nationwide.

RS Kanal- und Umweltservice GmbH has significantly advanced the combination of ultra-high-pressure water jetting and sewer robotics. The managing director of the Balingen-based company already operates 2 vehicles equipped with both the MicroGator and the MicroGator equipment carrier for ultra-high-pressure water jetting technology. In addition to the areas of application for ultra-high-pressure water jetting technology described here, RS Kanal- und Umweltservice uses the procedure successfully in other areas of application in sewers, including removing concrete, injection material, flat, solid adhesions or foreign bodies.