Pipe run measurement in the main sewer: A clear thing in Osnabrück

Job

Osnabrück produces around 49,000 cubic metres of wastewater every day. This corresponds to the capacity of 2,000 tanker trucks. 85,000 households with around 165,000 people and a large number of firms are connected to the sewer system. Over 1,000 kilometres of pipes, more than 90 retention basins, 38 large and around 300 small pumping stations and two modern sewage treatment plants ensure that stormwater and wastewater can flow after treatment into the rivers Hase and Düte. To ensure smooth, environmentally compatible sewer operation, the entire sewer system is inspected regularly and irregularities and defects are recorded. In Osnabrück, stormwater and wastewater are drained in a separate system. On average, the water takes two hours to travel from the centre of the city to the treatment plant.

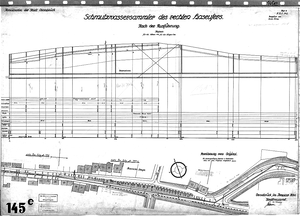

With a depth of up to 11 m, the sanitary sewer under Buersche Strasse, which was constructed using the gallery method, is the deepest sewer in Osnabrück. The ovoid cross-section sewer with diameters of DN 600/1050 is to be rehabilitated in trenchless construction over a length of around 475m. This is necessary because the sewer, which was built in 1913, is leaking in many places, extraneous water is infiltrating and there is isolated damage to the masonry. Up to now, only the digitized as-built plans from 1913 were available as a basis for planning. The radii of the bends were specified in these as R=10 m.

Challenge

In theory, the location of main sewers can be determined from manholes. These are visible above ground and are usually located in the public domain. It is generally assumed that the sewers run in a straight line between the manholes. However, there are always cases where the run of the sewer deviates from this principle to such an extent that the deviation is of importance for the planning of rehabilitation measures. To this end, the recording of the pipe run with width, length and height data should above all answer the question as to how it was possible to align the sewer with the bends in 1913, since the radii can be an exclusion criterion for certain closed construction methods.

Solution

SWO Netz GmbH decided to verify the information from the existing plans with the help of 3D GeoSense pipe run measurement. The new information on the pipe run is utilized for the further rehabilitation planning of LINDSCHULTE Ingenieurgesellschaft mbH.

First, the sewer was cleaned in preparation by means of a mobile ultra-high pressure water jet robot. Existing incrustations and adhering substances were removed. The inspection was then carried out using the ARGUS 5 pan, tilt and rotate camera. With this camera, which is designed for use in pipes of DN 200 and larger, the camera image always remains erect and non-reversed, even when the camera head is panned, tilted or rotated, so that the viewer can orientate himself without any problems. For the inspection, the sewage was pumped out and reintroduced into the sanitary sewer at a different point.

The ORION 2.9 3D pan and tilt camera was used for 3D GeoSense pipe run measurement. The x,y,z coordinates were determined while the camera was moving both forwards and in reverse. Each journey immediately provided a realistic site plan with the width, length and height data of the sanitary sewer on the monitor in the operator's section of the vehicle. The T 76 camera tractor has an electronic stability function that automatically returns it to the invert in the event of positional deviations. The powerful camera tractor guided the ORION 2.9 3D precisely through the main sewer so that the integrated sensor was always aligned parallel to the pipe axis. By averaging the measurements made during the forward and reverse journeys, small deviations could be minimized automatically, which is a function that is part of the IKAS evolution software component for 3D GeoSense pipe run measurements of sewer reaches.

In the course of further processing, the IKAS evolution software calculated the coordinates compatibly for all common sewer data formats from the captured sensor data. Thus, the resulting pipe run geometry could be transferred to the sewer database. After the pipe run geometry measured by 3D-GeoSense was imported into the database, it was compared with the existing data from the construction phase. The record of the pipe run with width, length and height data is in parts only slightly shifted parallel to the pipe run documented in 1913. Such exact data from 1913 was not to be expected beforehand, especially in view of the fact that the main sewer was built in rock using the tunnel construction method. The information and now established certainty about the exact radii of the bends provides planning security to those responsible and is a reliable basis for the decision to be made about the choice of a rehabilitation procedure.

Result

Continuous three-dimensional surveying has already established itself in the application area of branched connecting pipelines and has proven itself there many times with the most diverse types of orders and conditions. This practical case confirms once again that geodetic exact position surveying also provides valuable information for main pipelines: With 3D-GeoSense, non-rectilinear mains can be surveyed precisely. The planning data from 1913 could be confirmed and supplemented by exact curved dimensions. Thus, the xyz coordinates of the main sewer completed the information about the wastewater sewer to be rehabilitated. The comprehensive data serve SWO Netz GmbH and LINDSCHULTE Ingenieurgesellschaft mbH for selection, calculation and planning.

Company introduction

SWO Netz GmbH is a wholly owned subsidiary of Stadtwerke Osnabrück and is responsible for the planning, construction, operation and maintenance of infrastructure networks in the city.

LINDSCHULTE Ingenieurgesellschaft mbH is one of the leading independent consulting construction planning companies in Germany. A wide range of construction and engineering services are offered, from requirements planning to project execution.